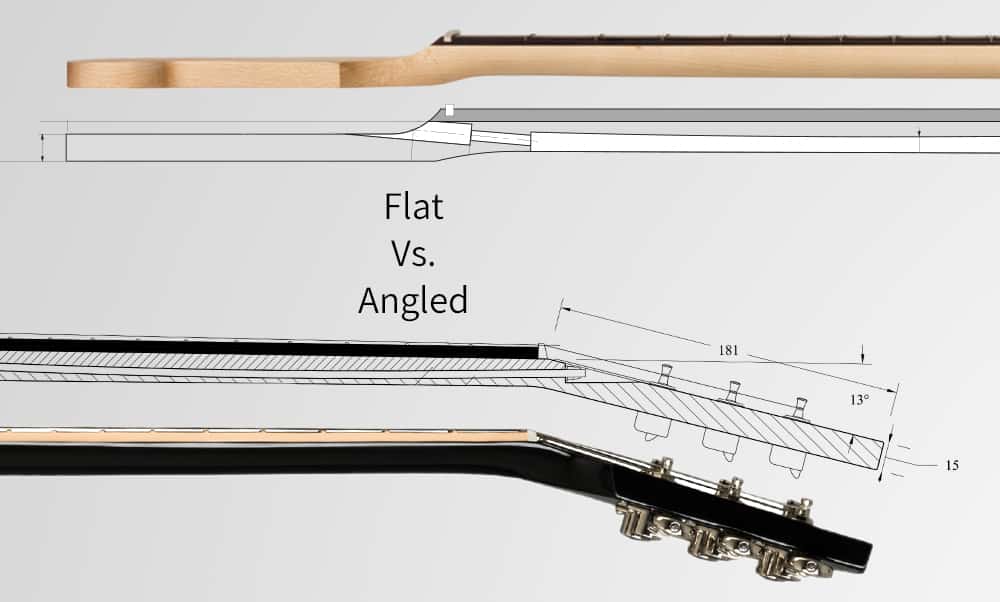

Stringed instruments and guitars, have traditionally been built with an angled headstock. It gives a nice break angle to the strings and puts pressure on the nut. This helps with intonation and also ‘holding’ the string from popping out of the nut. With the growing popularity of Fenders since the late 50’s, there are many guitars made with a flat neck

Which is better? Flat or Angled

While there is no disagreement on the fact that the string needs some angle between the nut (or zero fret) to the tuners, there are a different opinion to the angle of the headstock itself. These considerations include the break angle of the strings, the strength of the neck and headstock, production complexity, the amount of wood needed and practicality when playing the guitar.

In the following article I will try and look at all the angles of the headstock construction to understand and determine the pros and cons of Angled vs. Flat headstocks. There are wonderful guitars and players using them, of both angled and flat headstock, so the answer is surely not just one or the other. Looking at it from a builder’s point of view I am looking for a more educated reason to choose one method or another for any particular guitar or situation.

Why are guitar headstocks angled?

There a few reasons for headstocks being angled. Tradition, practicality and aesthetics.

Traditional reasons

When it comes to tradition, rational reasoning is not always necessary. It does however present a solution to a practical necessity guitars and other string instruments have always had. The Lute (after which Lutherie is named) has an almost 90-degree break angle. Classic/ Spanish guitar have an angle to them as well as acoustic guitars. Naturally early electric guitars adopted similar designs.

Practicality

Some pressure and break angle is essential to achieve good intonation. It also needed to hold the string in place to avoid slipping from the nut when bending. There may be other solutions for the practical issues, but some angle will need to be part of it.

Aesthetics

The look of a headstock may be very important for you or a customer and even if it has no practical implications, is a valid reason for many decisions made when it comes to guitar building. Just like choosing a one side vs. three and three tuner configuration (spoiler- they both work) an angled headstock can simply be a design choice. “It looks cool” is a valid argument.

What String Break Angle is ideal?

The question should may be specifying the use to which it needs to be ideal. Too shallow an angle may result in strings slipping from their slot, but will stay in tune better with bending and tremolo work. Too steep an angle will put more pressure on the string at the nut and with extensive tremolo work will damage them and cause tuning issues. This claim has to do with the ability of the string to slightly slip back and forth on the nut when being stretched and released. This can also be improved with different nut materials’ polishing and some lubrication.

Is there too shallow a break angle?

Even flat Fender style headstock have a break angle, and are also an example to what the minimal angle can be. The way these flat headstocks are built, the angle of string becomes shallower with the higher strings because of the growing distance to the tuner. The fact that Fender’s headstocks use string trees (retainers) on some of the strings is a testament to that they have too shallow an angle. So for practical intonation purposes these angles (about 6-7 degrees) are enough.

What are the most common angles?

If you are angling the headstock, 11 degrees is one of the most popular angles used. A large reason for that is that Gibson as well as Ibanez (and other smaller brands) use it on most of their guitars. PRS use 10 degrees. (Many Gibsons still use 17 degrees) Other models and manufacturers will vary in their angle and will use anything from the relatively shallow 5 degrees up to steep 25 degrees. Most will stay within the 8 to 15 degrees.

Are flat Headstocks stronger

The answer in short is yes, but it’s a bit more complicated. This has to do with both shape and grain direction. Another issue specific for angled headstocks is the construction method used to achieve the angle.

Wood grain Direction and Size

Wood is strongest along the grain. A flat headstock will maintain the same flow of grain and will give the optimal strength any given piece of wood can. An angled headstock made from a thicker piece of the same type of wood, will suffer short grain orientation at the angled area after it is cut to shape. This will make it more vulnerable to breakage, especially when also under tension from the strings. The remedy for this comes in the construction itself. as a ’scarf joint on which I will elaborate on later.

Angle Shape vulnerability

If we take a ‘standing’ Fender Stratocaster and a Gibson Les- Paul and just let them fall backwards to the floor (theoretically of-course), the Fender headstock will get hit very lightly as the back of the body will absorb a fair amount of the fall. The Gibson, however, has a slightly tilted neck and an angled headstock, so the force hitting the tip of that headstock will be much greater simply because of the shape of the guitar. It will take the full weight of the whole guitar. Add to that short grain orientation at the headstock and you get the infamous LP broken headstock.

The scarf joint - Better construction of the headstock angle

A second method to achieve an angled headstock is called a ‘scarf joint’. In this type of joint the blank neck piece is cut in the desired angle and the headstock end is flipped and glued back to the neck. This way the angled headstock still has long grain orientation and has no vulnerability in that area. As far as the joint itself is concerned in regards to strength, a properly executed glue joint is actually stronger than the wood around it.

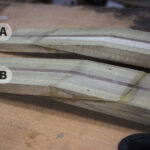

There are two methods of gluing a scarf joint. The difference is whether the ‘headstock’ piece is glued above or below the ‘neck’ part. They both work and if done correctly provide enough strength. The choice between the two has to do with aesthetics and personal preference of the Luthier.

The type ‘A’ scarf joint will have the seam in the middle of the front of the headstock and will often be covered for aesthetics reason. The type ‘B’ scarf joint may be visible at the back of the neck. At the front it will be covered by the fretboard, which may also provide some extra re-enforcement.

Production and building concerns

When Leo Fender dreamed up the Telecaster some of his concerns were strength, and production efficiency. The Fender Necks can be made from a minimal thickness of about an inch. An angled Gibson neck made from one piece of wood would have to be 3-4 times thicker and a large portion of it will go to waste. If the same neck was made with a scarf joint, it would require much less material, but will require another significant step in the production process and accommodating the now odd (non-flat) shape of the neck to the rest of the production. These may not be critical to a weekend warrior type of builder, but may be a concern for larger scale production.

Tuning Stability

There are claims of flatter heads and shallow angles maintaining better tuning stability. As I have mentioned before, there are many more factors to both tuning stability itself, and the ability of the string to slide in the nut slots themselves. While a steeper break angle will create more local pressure of the string on the nut, it is far from being the only, or the decisive factor. This will be even further put to the test when you introduce tremolos into the mix.

Better tone/ longer sustain

The same pressure that is blamed for bad tuning stability is often hailed for providing better tone and longer sustain. As anything in the guitar world that has to do with tone and the illusive sustain, it is often very subjective and it would be extremely difficult to get any objective or scientific data on the subject. If a person tells me they can hear minute differences, I can contribute that to either better hearing than I posses (very possible) or a subjective feeling. Both are hard to prove or refute.

Variations and solutions

Over the years, aside from playing around with the angle itself, there have been a few parts and tricks to help and improve these issues.

String Retainers

I am not refereeing to single string trees but rather one rod that presses and holds all 6 strings right after the nut. In theory, the height of the retainer determines the string break angle and behind the retainer there should be no consequence to the headstock angle. You do need to take into account that the greater the pressure of the retainer on the strings, the more friction it will create which may be a whole new issue to deal with.

Locking Nuts

With the growing popularity of floating tremolo bridges such as Floyd Rose, on the other end of the strings are the locking nuts. When locked these nuts actually hold the string and should eliminate any motion between the nut and the tuners therefore making the headstock angle irrelevant. For better use many come with a string retainer to lower and equalize the height of the strings at the nut. Once the nut is locked though, the retainer has no effect on the strings or sound.

Staggered-Height Tuners

A few years ago, somebody came up with the idea of making the tuning pegs shorter the further away they are from the nut. This was supposed to ‘solve’ the problem of string trees in flat Fender style headstocks. While the idea seems nice, in many cases the shortest tuner, which would usually be the high E string, is not low enough to make a significant enough change to the angle and therefore still requires a string tree. I am not sure why some people hate those trees so much’ there are a few very handy and nice-looking ones you can always change to.

Conclusion

At the end of the day each design has its appeal, it’s drawbacks and strengths. There are wonderful guitars incorporating all these types of headstock angles and if you are building a guitar, it is up to you to decide which approach will fit your taste, your tools, your capabilities or your dreams. Personally, I am fine with flat headstock and I have lately been leaning towards the Music Man style headstock but instead of the 4-2 tuner configuration, I am aiming for a 3-3. This short flat headstock eliminates the need for string trees while kipping the build simple strong and effective. It also requires the minimal amount of timber.

Hope this will help you make some choices when you come to building your own guitar.